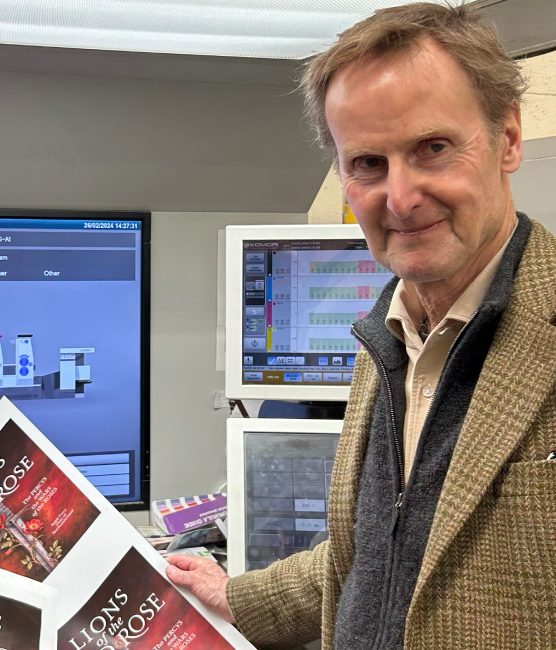

Lions of the Red Rose

Statex is delighted that the Duke of Northumberland has entrusted us with…

Read moreWhen it comes to commercial printing, there are many different options to choose from to achieve your desired result that it can be a little overwhelming when deciding on the most appropriate printing method for you and your business. From a new company brochure or business cards for your latest team of recruits, there are typically two types of printing processes that will be offered to you – lithographic (often referred to simply as litho) printing, and digital printing.

The type of printing you pick will impact not only the outcome of the finished product, but the budget, timeframe, material, and quality; so it’s important you understand the difference between these two. In this article, therefore, we’re exploring what lithographic and digital printing actually is – outlining their differences to help you make well-informed decisions.

What is lithographic printing?

The more traditional method of the two, litho printing is the process of transferring a copy of your content onto a plate that is then covered in thick liquid ink and printed onto paper using fast-moving rollers – a bit like a stencil. It is for this reason that this form of printing is also widely known as ‘offset litho printing’, as the image is offset across the plates, rollers, and finally, the material.

Generally carried out in high-volume jobs, this process can be used to print images and words not only on paper, but cardboard and many other materials too. This technique is great for printing bigger areas of solid colour as it’s not limited to a four-colour process used in digital printing – making large blocks of single colour appear smooth.

In essence, digital printing uses electronic files, like PDF artwork, to produce an image that is then lasered onto paper and printed using toner instead of ink.

This process, carried out by digital print machines, is incredibly fast and of a high quality. In addition, because no printing plates are needed, the setup required for a digital print job is very minimal; making this technique very cost-effective for smaller runs.

Simply put, the difference between lithographic printing and digital printing is that the former uses wet ink and printing plates, while the latter uses toner. But there a few more things that come into play that will affect what you decide to use, including the following.

Digital print is more limited to the types of materials they can print on and is used for smaller volumes and quick response times. Litho printing, on the other hand, uses a wider range of papers and boards and also allows for larger sheet sizes.

Therefore, if you’re looking to print on a particularly thick piece of paper of a different type of material, it’s most advisable to consider lithographic printing.

Due to the initial preparation involved in offset litho printing through the use of printing plates and wet ink as opposed to toner (which is more of a dry, powdered substance), lithographic printing has a longer turnaround time compared with its digital counterpart.

So, if you find yourself up against a looming deadline, you may decide that digital printing is the best option for you to produce high-quality materials, quickly.

Because digital printing uses electronic files as opposed to plates, your printed material can be personalised with a few small tweaks to the file on your desktop – for example, a direct mail campaign could include the name of each recipient in the design and be printed as such. Lithographic printing, on the other hand, requires printing plates to be made, so each alteration to the design will require a new plate to be created – impacting both time and cost.

Therefore, when it comes to customising your printing material, digital printing is widely recognised as the best option for this style of printed material.

For further information on the differences between lithographic and digital printing, or to speak with a specialist about your next print job, get in touch with Statex today.